Stereotactic radiosurgery (SRS) is a precision-targeted radiotherapy technique that has registered significant success in treating single and metastatic tumours in the brain. By employing multiple narrow beams from different directions, radiation oncology teams are able to deliver conformal, high-dose radiation in one or a few fractions while minimizing collateral damage to surrounding healthy tissue and organs at risk. When used to treat tumours elsewhere in the body – for example, the lungs, liver and spine – these high-precision, high-dose techniques are known collectively as stereotactic body radiotherapy (SBRT).

Taken together, the growing clinical adoption of SRS/SBRT represents a significant dosimetric and quality assurance (QA) challenge for medical physicists and radiation therapy departments – not least in terms of the small treatment volumes (down to 0.75 cm3) versus standard conformal radiotherapy. The precision targeting inherent to SRS/SBRT means that all manner of different checks – machine, patient and end-to-end QA – are necessary to manage, verify and validate the treatment procedure to ensure that radiation is being delivered to the patient as intended (i.e. overall treatment accuracy needs to match the treatment planning margins of 0–1 mm).

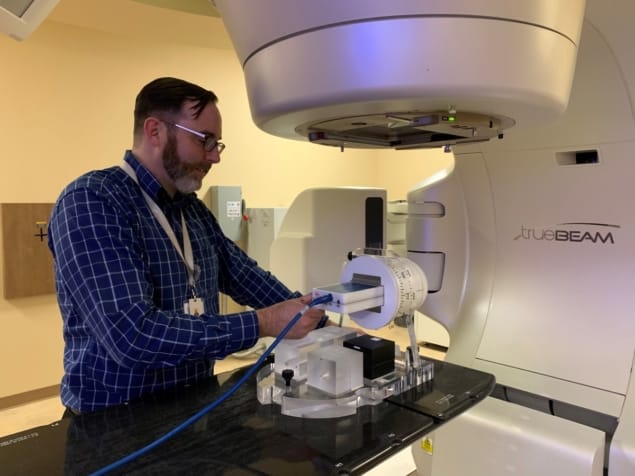

“Patient QA with SRS MapCHECK has become a routine part of our SRS/SBRT workflow,” says Brett Miller, chief physicist (radiation oncology) at the University of Tennessee Medical Center. (Courtesy: University of Tennessee Medical Center)

Innovation in quality assurance

To support the ongoing clinical uptake of SRS/SBRT applications, Sun Nuclear Corporation, a US-based provider of QA solutions for radiation oncology, has prioritized development and innovation across a broad portfolio of products specifically for clinical teams delivering stereotactic procedures. “We take very seriously our role as an independent QA provider for SRS/SBRT,” says Jennifer Hamilton, a staff medical physicist at Sun Nuclear. “We’ve always believed that QA workflow has to be simple and user-friendly, or it won’t be done effectively.”

With that in mind, Hamilton says the focus at Sun Nuclear is “on getting the science right and standing behind the customer and the products”. Of Sun’s 300+ staff worldwide, the company employs more than 40 physicists, with around a third of the total workforce in R&D roles and 15% in customer support.

"This gives us high-quality patient QA in minutes rather than hours and significantly enhanced patient throughput."

- Brett Miller, University of Tennessee Medical Center

At the heart of the vendor’s SRS/SBRT offering is the StereoPHAN phantom, designed for end-to-end commissioning and QA testing on all parts of the treatment process, including QA of image-fusion algorithms for CT and MRI as well as diode array, film and single-point ion-chamber dose measurements.

“StereoPHAN is incredibly easy to use,” says Hamilton. “It requires no tools, it indexes to the treatment table, and it does all the tests that the medical physicist needs to do for SRS end-to-end testing. A big plus is that it’s easy to quickly reconfigure for different needs, unlike a lot of other phantoms.”

The QA benefits are workflow efficiency and measurement accuracy. “After all,” adds Hamilton, “if I’m doing an end-to-end QA test and I have to use a screwdriver to take apart a phantom and then put it back together, how do I know I haven’t introduced positional error?”

Optimizing the workflow

Another core building block in Sun Nuclear’s SRS/SBRT portfolio is the SRS MapCHECK, a high-density diode array for patient-specific QA and end-to-end testing that’s billed as an “efficient digital alternative to film for small-field dosimetry”.

Designed to insert into the StereoPHAN, the SRS MapCHECK comprises 1013 silicon diodes, each with an active area of only 0.5 mm2, in a 77×77 mm effective measurement area – an arrangement that enables absolute dose measurement of field sizes as small as 5 mm with the tight spatial resolution (2.47 mm centre-to-centre) needed for SRS/SBRT.

“Prior to SRS MapCHECK, there really wasn’t an appropriate QA tool for SRS patient QA outside of film,” notes Hamilton. “However, the problem with film is that it’s temperamental and extremely time-consuming. To get consistently accurate absolute dose out of film the user needs to have really tight controls on their process. You can do it – it’s just painful.”

Among the early-adopters of SRS MapCHECK was Brett Miller, chief physicist (radiation oncology) at the University of Tennessee Medical Center. Miller heads up a team of eight medical physicists and dosimetrists, and he is responsible for all aspects of radiotherapy QA and treatment planning at the Knoxville clinic. “The use of SRS [for brain] and SBRT [for lung, spine, and liver] has ramped up over the past couple of years and remains on an upward trajectory,” he explains.

Miller and his team were among the initial beta sites to evaluate SRS MapCHECK, starting in early 2018. Deployment into the daily clinical workflow followed about nine months ago, says Miller, yielding significant time savings and efficiencies along the way.

“Patient QA with SRS MapCHECK has become a routine part of our SRS/SBRT workflow, whereas before [with film dosimetry] it was a bit of a bottleneck,” he notes. “Ultimately, this gives us high-quality patient QA in minutes rather than hours and significantly enhanced patient throughput. It’s a win-win.”

What’s more, the whole point of SRS/SBRT is to focus high-dose radiation very precisely and have it fall off as quickly as possible to spare healthy tissue and nearby organs at risk. “SRS MapCHECK has very high spatial resolution, and a very small detector active area, so you can get a lot more detectors with precise measurement capability in a small field and actually see some of those high dose gradients,” explains Miller. “It allows you to confirm your targeting accuracy and your dose distribution accuracy.”

Hitting the spot

The Tennessee experience suggests that SRS MapCHECK has hit the sweet-spot in terms of SRS/SBRT QA, a view reinforced by the fact that more than 200 SRS MapCHECK units have been ordered since commercial release.

“We spent a lot of time ensuring that the small-field factors were accurate for SRS MapCHECK and I think the R&D team has done a fantastic job,” explains Hamilton. “We’ve also applied automatic angular dose corrections. Ours is the only 2D diode array with this capability and it means you can shoot at SRS MapCHECK from any angle – essential for SRS/SBRT where you’re rotating everything.”

In terms of next steps, R&D testing is now complete on a version of SRS MapCHECK that provides compatibility with Accuray’s CyberKnife robotic SRS/SBRT system and Varian’s HyperArc system. Commercial release will follow soon. “CyberKnife users are eagerly awaiting this next release,” Hamilton adds. “They’re ready for a patient QA tool that’s easier to use than film.”

Getting to grips with off-axis targets

Another Sun Nuclear QA product that’s generating plenty of clinical interest is the MultiMet-WL Cube, an insert for the StereoPHAN phantom that enables medical physics teams to verify the accuracy of single-isocentre, multiple-metastasis SRS treatments. The problem this product is addressing is radial propagation of error, explains Hamilton. “In other words, if you have a very small offset in the very centre of your field, and then have large rotations in your plan, by the time you get out to the edge of your field that error could be really large – much larger than you can tolerate.”

Another Sun Nuclear QA product that’s generating plenty of clinical interest is the MultiMet-WLCube, an insert for the StereoPHAN phantom that enables medical physics teams to verify the accuracy of single-isocentre, multiple-metastasis SRS treatments.

The problem this product is addressing is radial propagation of error, explains Hamilton. “In other words, if you have a very small offset in the very centre of your field, and then have large rotations in your plan, by the time you get out to the edge of your field that error could be really large – much larger than you can tolerate.”

This translates into a significant issue now that so many clinics are adopting multiple-metastasis, single-isocentre treatments over the whole brain. Hamilton continues: “The MultiMet-WL Cube is a simple way for medical physicists to measure within 0.1 mm accuracy the precision of their off-axis targets out to a range of 7 cm off-axis. It’s letting you know what your error is so that you can plan for it – ultimately yielding better targeting and better clinical outcomes.”

Sun Nuclear physicists, in collaboration with the radiation oncology team at Baptist Hospital in Miami, US, will present a clinical evaluation of the MultiMet-WL Cube at the upcoming AAPM Annual Meeting. They conclude that the MultiMet-WL Cube is a “readily usable off-the-shelf solution and a clinically useful tool for machine daily QA…and an effective supplementary tool for end-to-end testing for SRS”.

This article was originally published on Physics World